about Audio, High Fidelity

& Home Entertainment technologies

pid: 607-2025/10/01 (v1.2)

Privacy Policy

Type 612 & Type 602 Mastering Lathe

Text: Dimitris Stamatakos, Photos: avmentor.net

The intense heat of the Greek summer could not, surely, serve as an excuse to miss such an opportunity. Even though the phone rang early in the morning and the setting of the presentation was not strictly audio-related—since the principal theme of the international Philos 2025 symposium is more philosophical than technical—the presentation titled “Striving for Analog Perfection and Expanding Degrees of Freedom” by Agnew, was sufficiently provocative, as it included the on-site cutting of sounds from the conference onto vinyl records and distributing them to the delegates. To accomplish this, of course, a record-cutting machine was required—and that is precisely the subject of the following paragraphs.

Jesus and I have been acquainted for some years now. Our first contact occurred on the occasion of this article, and we continued in 2022 when he participated as a speaker at a workshop during that year’s Black Box AV Show.

The Agnew Analog Type 612/Type 602 system is the first genuinely new disc-cutting system in a long time, and it is not merely a new implementation based on traditional ideas, but also incorporates a series of new solutions.

I have been aware for a long time of Jesus’s work on cutting-machine technology through conversations we had and articles I've read (the article “An Investigation of Motional Feedback Disk Recording System Design” in the JAES is, to say the least, indicative of his intentions), but—disclaimer—I also had some inside information about the progress of the project at the production level from here, since the high-end machine shop (eksartimata.gr) where many parts of the machine were manufactured belongs to my brother, Konstantinos. Life is indeed strange sometimes…

Many of us own hundreds or even thousands of vinyl records, yet the likelihood of having seen a cutting machine up close is very small. The likelihood of seeing one in operation is even thinner, since the evolution of the medium over recent decades leaves little room for such encounters. Personally, I have come across such machines only a few times (at exhibitions and conferences), but never seen one in operation. The case of the Philos 2025 symposium demo was the opposite of this situation: we are talking about an impromptu setup, with the entire system installed in a trailer vehicle that arrived from Chalkidiki (where the headquarters of Agnew Analog are), following the principle of form follows function. Transporting and installing such equipment, for temporary operation, is by no means easy.

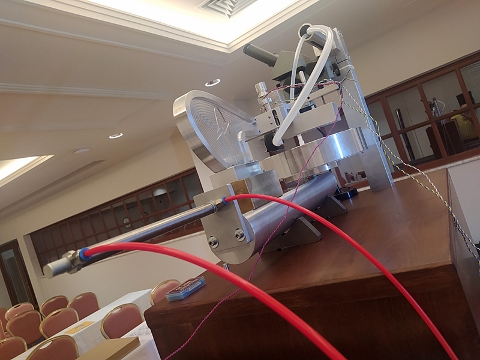

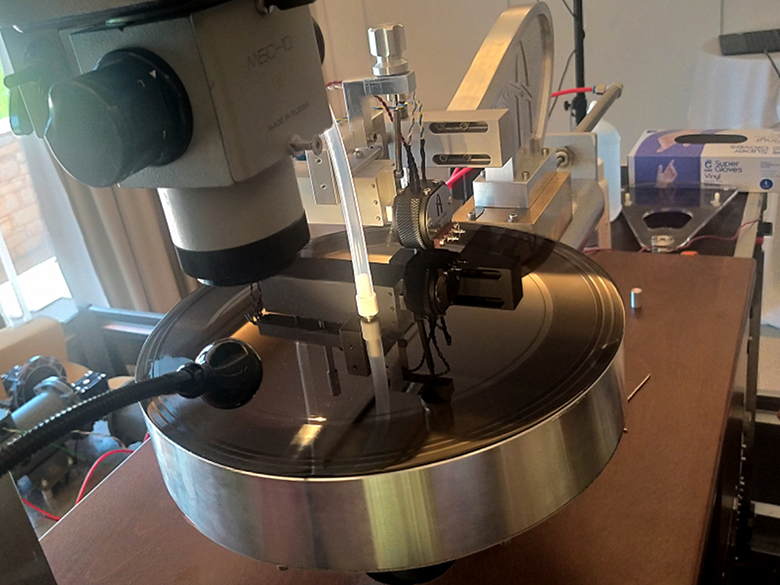

What exactly is such a machine? What are its constituent parts, and what has Agnew Analog built in 2025, when the traditional manufacturers have long since retired? A cutting lathe consists of four main sections: the bed, upon which the movable carriage of the cutting head slides; the cutting head itself; and the platter. Naturally, there is also a large number of peripheral components that are particularly critical; however, this is the general picture.

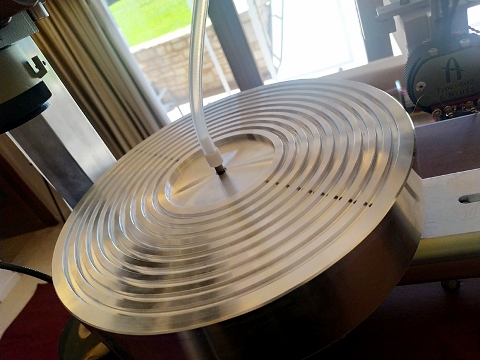

The platter is specially designed to create a vacuum beneath the disc. This ensures full contact between disc and platter (and therefore complete leveling of the disc) and the necessary stability.

The platter is designed to create a vacuum to secure the disc being cut (a technique also used in some high-end playback turntables), and its rotation is driven by a motor that, in addition to providing rotational stability, must also deliver sufficient power to overcome the resistance created by the cutting process itself. The vacuum platter is supported by a hydrodynamic oil bath bearing unit, which suspends the platter shaft on a film of oil, both radially and axially, eliminating metal-to-metal contact.

To all of the above, one must add the necessary electronics (the head is driven by large power amplifiers because cutting requires substantial power) and a mechanism for moving the carriage. At this point comes Agnew Analog’s first innovation in the case of the Type 612. The carriage is not advanced mechanically (usually a lead screw is used here) but hydraulically—an approach which ensures lower noise and greater reliability, particularly over the long term.

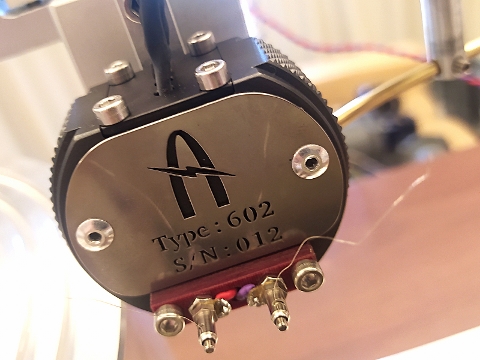

The Type 602 cutting head. Its operating principle belongs to none of the conventional schools (moving coil, moving magnet or moving iron), and Agnew is, for the moment, withholding details.

Because the carriage motion spans a large range of steps (very small steps during cutting, larger steps during lead-in and lead-out), the system has a dual circuit with two pumps that are activated depending on the motion required.

Agnew has placed great emphasis on geometric precision and rigidity. For this reason, the machine’s lathe bed integrates both the platter bearing and the sliding surface of the cutting carriage. In conventional designs, these two parts are assembled onto the bed with some form of mounting system

This is the heart of the hydraulic system, which moves the cutting carriage. It uses two different pumps to ensure correct motion both during cutting and during the formation of the lead-in and lead-out grooves of the disc.

There is a lubrication mechanism to ensure low friction during sliding, and the platter bearing itself has an automatic lubrication system. The slideway is machined directly onto the bed, and the system is self-adjusting and self-compensating for wear, ensuring that the initial high accuracy built into these machines will remain for the entirety of their long service life. The platter is available in two diameters, 12 and 14 inches, and is driven by a motor mounted at the bottom of the system.

The vacuum platter is adjustable, both for run-out and eccentricity, typically achieving errors of less than ±0.1um in magnitude. The geometric accuracy of each machine is checked with an autocollimator, an optical measurement instrument that can detect errors that would be beyond the detection threshold of more common laboratory instruments.

Disc cutting is performed by Agnew Reference’s Type 602 head. Here, Jesus reveals very little, as its operating principle is, for the time being, a trade secret. He merely stated that it is something entirely different from the conventional heads used over the last many decades and reserves full disclosure for future academy publication. What is stated is that it is a system capable of cutting levels much higher than those a playback system can withstand and that it is built to endure heavy use. The cutting stylus itself is a model readily available on the market. The company also notes that a version suitable for DMM (Direct Metal Mastering—cutting directly onto a metal disc rather than lacquer, as is conventional) is under development.

Jesus Agnew is getting ready to make the first test cut of the day. The system requires a cleaning and moisture-removal procedure before it begins operation.

The basic configuration of the machine (as set up at the PHILOS 2025 conference) has no automation. Instead, it consisted of very old-fashioned, large and heavy components with an expected maintenance-free service life of several decades, built to military standards and resistant to EMI/RFI and even EMP events. However, Agnew Analog also offers kits for retrofitting any of the aftermarket lathe automation systems ever made, making the system entirely compatible with all kinds of automation for those who need them.

The machine shop eksartimata.gr is responsible for manufacturing many of the components of the Type 612/Type 602 system. Kostas Stamatakos is the founder and guiding mind behind this endeavor.

The Agnew Reference system is manufactured both in Greece and in Scotland (at Glasgow Analog, a company founded specifically for this purpose). It can be delivered as a complete, turnkey solution or in parts, so that anyone wishing to integrate only what they need into their own system may do so; the Type 602 head can be mounted on any other cutting machine. Agnew Reference also offers support and training both for operation and for routine maintenance of the system.

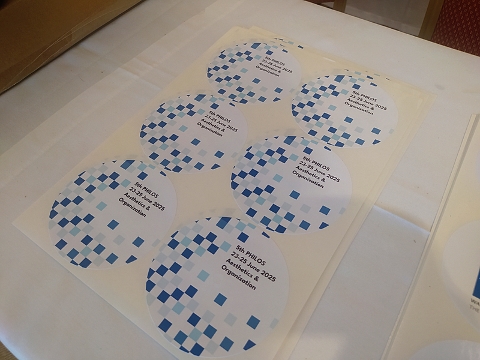

Within the framework of the symposium, sounds and speeches were recorded and became the material cut onto discs by Agnew Analog’s machine. Here are the labels of the records.

For more information: https://agnewanalog.com/